Auctech robotics

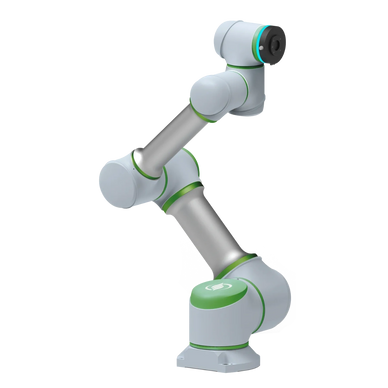

X series cobots

SCARA Industrial robots

SCARA Industrial robots

There are ten types of 6-axis cobot: X30-1100, X25-1800, X20-1400, X16-2000, X16-960, X12-1300, X10-1300, X7-910, X5-910, X3-618. With significant advantages of higher payload and working range, and features of cobot such as collaborative safety, easy-to-use and energy-saving, these robots can adapt to more application needs.

The controller is used to control the robot's operations such as loading and unloading, grasping, polishing, handling, welding, gluing

and oiling, as well as realizing the input and output control.

SCARA Industrial robots

SCARA Industrial robots

SCARA Industrial robots

AUCTECH industrial robots are faster, more reliable, and more precise.

Every second and every motion of industrial robots matter throughout manufacturing, and that explains why robot reliability and speed come first for us.

After years of updating and improving, our products have become faster and more reliable, with more functions integrated into a compact size. That makes applications easier, production more stable, and intelligent manufacturing more efficient.

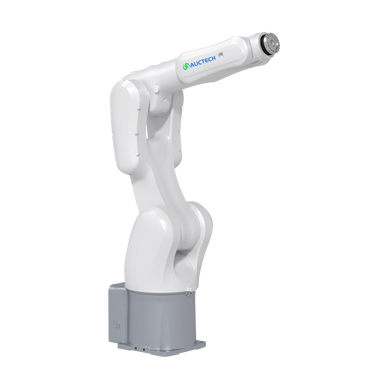

BM Series 6-axis Robot

SCARA Industrial robots

BM Series 6-axis Robot

AUCTECH industrial robots are faster, more reliable, and more precise.

Every second and every motion of industrial robots matter throughout manufacturing, and that explains why robot reliability and speed come first for us.

After years of updating and improving, our products have become faster and more reliable, with more functions integrated into a compact size. That makes applications easier, production more stable, and intelligent manufacturing more efficient.

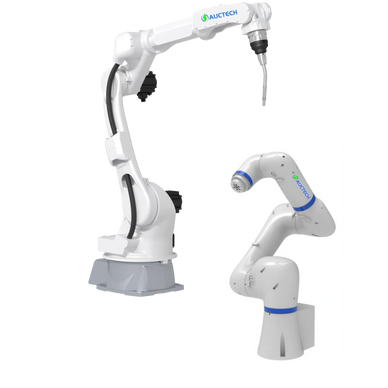

Welding cobot and robot

AHP Series Palletizing Robot

BM Series 6-axis Robot

H Series is AUCTECH's industrial collaborative welding robot series, integrating high protection, robust performance, and intelligent operation. Featuring an IP67-rated body with servo systems. Built-in torque sensors enable collision emergency stops, ensuring human-robot collaboration safety. The drag-to-teach programming simplifies trajectory calibration with a user-friendly interface. High-precision motion control and laser seam tracking, paired with 100+ smart process libraries (fish-scale/weaving welding), achieve high weld quality. Modular design supports mobile vehicles and magnetic bases for confined spaces, shipbuilding, and steel structures, redefining welding efficiency with high rigidity, reliability, and adaptability.

AHP Series Palletizing Robot

AHP Series Palletizing Robot

AHP Series Palletizing Robot

AWP Series is AUCTECH's collaborative palletizing workstation solution, integrating intelligence, safety, and easy deployment for light industrial applications. Offering payloads of 20-50kg and a working radius of 1.48-1.98m (±0.05mm accuracy), it supports vacuum grippers/mechanical claws for boxes, sheets, and bottles, achieving 8-12pcs/min efficiency. Designed for plug-and-play deployment, flexible scalability, and low maintenance costs, it drives intelligent upgrades in batch production for food, pharmaceuticals, and daily chemicals.

Copyright © 2026 MAK SERVO - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.